Time:2026-02-10 10:27:19 Hits:

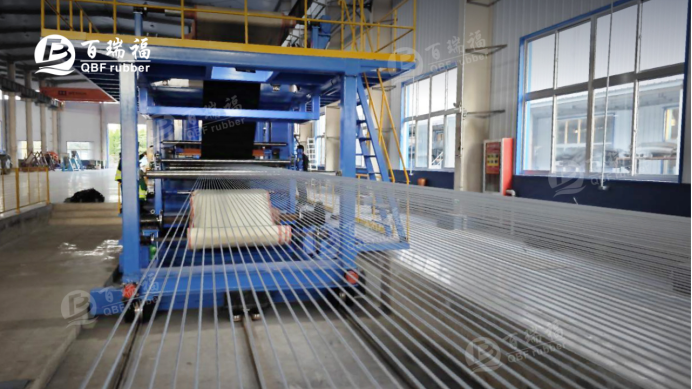

In today's industrial landscape where environmental protection and efficiency are core demands, pipe conveyor belts, with their outstanding features of enclosed dust-free operation, spatial curvature capability, and environmental friendliness, are increasingly becoming the preferred solution for material conveying in complex terrains and harsh conditions. The core lies in achieving the precise transformation from a "flat" to a "tubular" form.

QBF rubber, with years of deep expertise in the specialty conveyor belt field, has successfully established a high-performance pipe conveyor belt production system through continuous technological R&D and process refinement. This system integrates cutting-edge material science, precision structural design, and intelligent production control, delivering reliable conveying solutions that exceed customer expectations.

· Utilizing special steel cords with high modulus and low elongation, embedded into the belt's core with precise spacing and tension, endows the conveyor belt with extremely high longitudinal tensile strength. This ensures that the skeleton does not undergo permanent deformation during complex spatial bends, truly enabling high capacity, long-distance, and robust performance.

· Developing specialized cover rubber compounds tailored to the abrasive characteristics of different materials such as coal, ore, and cement. This gives the cover layer superior wear resistance, impact resistance, and environmental aging resistance, ensuring the pipe conveyor belt is wear-resistant, impact-resistant, and durable.

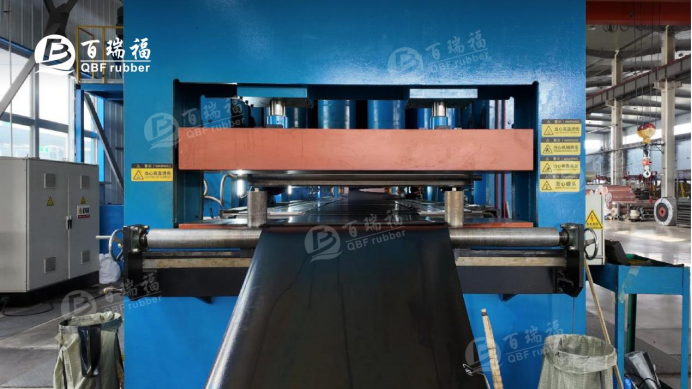

· The high-temperature, high-pressure integrated vulcanization process grants the product uniform ultra-high strength, excellent fatigue resistance, and dimensional stability, achieving structural integrity, strong adhesion, and stable form.

· Dynamic cycle testing before leaving the factory (covering key indicators such as tube formation sealing, minimum turning radius, stability under full load operation, and fatigue strength of splice joints) ensures its reliability in actual complex conveying routes.

The manufacturing of QBF rubber Pipe Conveyor Belts represents a profound practice in reliability, environmental sustainability, and economic efficiency. By fusing materials, processes, and intelligent control, we have successfully elevated two-dimensional flat conveying to three-dimensional spatial closed-loop operation. This not only safeguards the environment but also creates sustained value for customers through lower comprehensive operational costs over the entire lifecycle.

*Please fill in the required information carefully, and we will contact you within 24 hours.

Professional brand of European standard long-life side guard belt

Expert in low-carbon intelligent transportation services for bulk materials

Copyright © 2023-2024 QBF All rights reserved Record number:鲁ICP备12028203号-1

Technical support: WDL